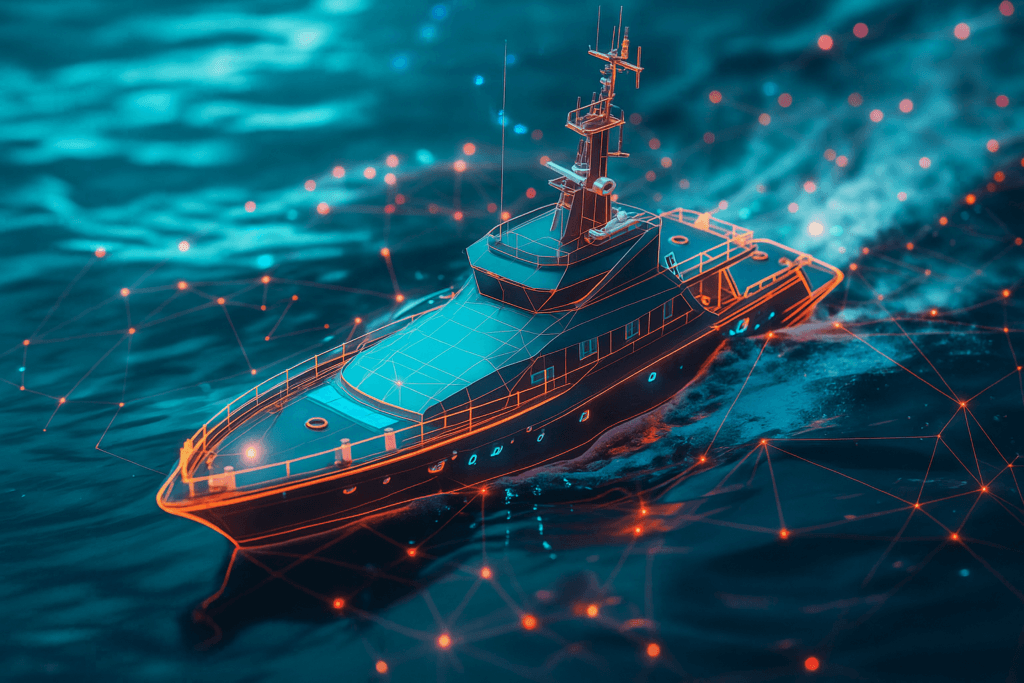

Maritime operations have always relied heavily on energy to power management systems, onboard electronics, lighting, and climate control.

Modern ships consume vast amounts of energy, making efficient power management critical for cost savings, safety, and environmental compliance.

With rising fuel prices and stricter emission regulations, shipping companies are increasingly looking for ways to optimize energy use.

Current Power Management Practices in Maritime Applications

Most ships today use conventional diesel engines and generator sets to provide propulsion and electricity for onboard systems.

Auxiliary systems such as lighting, HVAC, and communication equipment rely on these generators. Energy monitoring is typically done through onboard meters and manual checks.

While these methods are effective to an extent, they often lack the ability to respond dynamically to changing conditions and optimize energy usage in real-time.

Challenges in Maritime Power Management

Ships face several challenges when it comes to power management. High fuel consumption leads to significant operational costs.

Strict emission regulations require operators to reduce greenhouse gas and pollutant outputs. Balancing energy between propulsion and auxiliary systems can be complex, especially during peak operational demands.

Maintenance and operational complexity further add to the challenge, as older engines and systems are less efficient and harder to manage.

Emerging Technologies Shaping the Future

The maritime industry is exploring several new technologies to improve energy efficiency. Hybrid propulsion systems that combine diesel engines with electric motors reduce fuel consumption and emissions.

Fully electric vessels are becoming feasible for short-sea and inland shipping operations. Energy storage solutions such as batteries, supercapacitors, and hydrogen fuel cells allow ships to store and use energy more efficiently.

Renewable energy integration, including solar panels and wind-assisted propulsion, helps reduce reliance on fossil fuels and lower the carbon footprint.

Smart Power Management Systems

Advanced digital systems are transforming how ships manage energy. AI and machine learning can predict energy needs and optimize usage automatically.

Real-time monitoring allows crews to see exactly how energy is being used throughout the vessel. Automated load balancing ensures that propulsion and auxiliary systems operate efficiently without wasting energy.

Predictive maintenance identifies potential equipment issues before they cause inefficiency or downtime.

Energy Efficiency Strategies

Improving energy efficiency goes beyond technology. Optimizing engine operation and fuel usage helps reduce costs and emissions.

Waste heat recovery systems capture energy from engine exhaust to power onboard systems. Efficient HVAC and lighting systems reduce auxiliary energy demand.

Operational strategies such as route optimization and speed management help save fuel and make power usage more efficient across the journey.

Conclusion

The future of power management in maritime applications is focused on efficiency, sustainability, and reliability.

By combining advanced propulsion systems, energy storage, smart monitoring, and operational strategies, shipping companies can reduce fuel costs and environmental impact.

Adopting these innovative practices is essential for the next generation of maritime operations and for meeting global sustainability goals.