The automotive industry has always been synonymous with innovation and cutting-edge technology. As consumer expectations evolve and environmental concerns become more pressing, the demand for smarter, more efficient vehicles has grown exponentially.

This evolution requires automotive manufacturers to rethink traditional design processes, aiming for speed, precision, and adaptability. One of the most transformative technologies driving this change is Artificial Intelligence (AI).

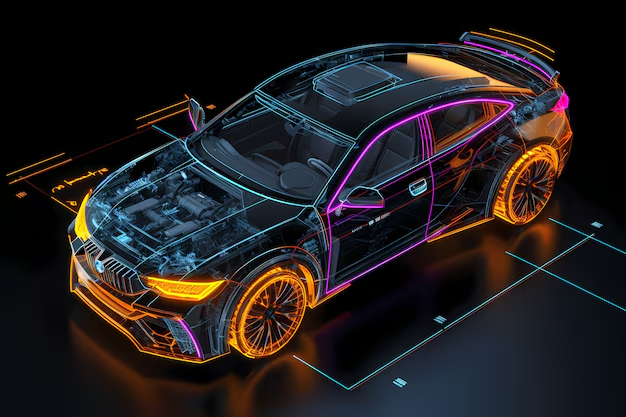

AI is revolutionizing every aspect of automotive design and prototyping, from initial sketches and material selection to virtual testing and advanced manufacturing.

By leveraging AI, automotive designers can now explore endless design possibilities, validate concepts with unparalleled accuracy, and shorten the time it takes to bring a vehicle from the drawing board to the production line.

This not only speeds up innovation but also helps companies stay competitive in a market that demands continuous improvements in safety, efficiency, and user experience.

In this blog, we delve into how AI is streamlining the automotive design process, making it possible to build prototypes faster, optimize vehicle performance, and meet the needs of a more dynamic market.

From generative design to virtual prototyping and beyond, we’ll explore how AI is shaping the future of vehicle innovation, driving the industry toward a new era of intelligent transportation.

The Role of AI in Vehicle Design

Artificial Intelligence (AI) has emerged as a game-changer in vehicle design, enabling automotive engineers and designers to push the boundaries of creativity and functionality. Here are some key ways AI plays a crucial role in this transformative process:

Generative Design

Generative design represents a paradigm shift in how automotive designers approach the creation of vehicle components. By inputting specific parameters—such as weight, material type, manufacturing methods, and cost—AI algorithms can explore countless design alternatives.

This approach allows designers to evaluate multiple iterations, optimizing for various factors like strength, weight reduction, and aerodynamics. For example, companies like General Motors and Autodesk have successfully implemented generative design to produce lighter, stronger components that improve overall vehicle performance and efficiency.

Virtual Prototyping

In the past, creating physical prototypes was a time-consuming and costly endeavor. AI has streamlined this process through virtual prototyping, where digital models are created and tested in simulated environments. This allows engineers to visualize designs and assess performance without the need for physical production.

By employing AI-driven simulations, manufacturers can identify potential issues early in the design phase, reducing costly errors and iterations. Companies like Tesla utilize advanced virtual prototyping techniques to iterate rapidly on their vehicle designs, ensuring that only the best concepts move forward to production.

Design Validation and Simulation

AI-powered simulation tools are crucial for validating vehicle designs under various real-world conditions. These tools can perform complex analyses, such as crash simulations, thermal performance assessments, and aerodynamics studies, to ensure that vehicles meet safety standards and performance expectations.

For instance, automotive manufacturers can use AI algorithms to simulate how different materials and shapes affect a vehicle’s crashworthiness. This process not only enhances safety but also accelerates the regulatory approval process by providing robust data to demonstrate compliance with safety regulations.

Enhanced Collaboration and Workflow Optimization

AI also facilitates collaboration among design teams by streamlining workflows and improving communication. AI-driven platforms can analyze project timelines, resource allocation, and team performance to identify bottlenecks and suggest optimizations. This enables teams to focus on high-value tasks and reduces the time spent on administrative duties.

Moreover, AI tools can integrate with various design software, allowing for seamless collaboration between engineers, designers, and other stakeholders. By enhancing communication and optimizing workflows, AI ensures that vehicle designs are completed efficiently and effectively.

Data-Driven Insights

With the increasing amount of data available from previous vehicle designs, AI can leverage historical performance metrics to inform new designs. Machine learning algorithms can analyze patterns and correlations in data, helping designers make informed decisions based on past successes and failures.

This data-driven approach allows manufacturers to refine their designs continually, enhancing safety, performance, and consumer satisfaction. As AI systems learn from vast datasets, they can predict design outcomes more accurately, leading to innovative solutions tailored to market demands.

AI in Prototyping and Manufacturing

As the automotive industry continues to advance, the need for rapid prototyping and efficient manufacturing processes has become more critical than ever. AI technologies are at the forefront of transforming these areas, significantly enhancing speed, accuracy, and overall production efficiency.

Here are several key aspects of how AI is revolutionizing prototyping and manufacturing in the automotive sector:

Accelerating Prototyping Processes

Traditionally, creating physical prototypes of vehicles is a lengthy and costly process. However, AI is accelerating this timeline significantly. By utilizing AI algorithms, automotive manufacturers can quickly generate virtual prototypes that can be tested in simulated environments.

This allows teams to iterate designs rapidly without the need for multiple physical models. Technologies such as 3D printing, powered by AI, enable the production of complex components at unprecedented speeds. For instance, companies like BMW and Ford are increasingly relying on AI to streamline their prototyping processes, allowing them to bring innovative designs to market faster.

AI in Material Selection

Material selection is a critical aspect of automotive design, impacting factors like weight, cost, and performance. AI can assist engineers in optimizing material choices by analyzing vast datasets to identify the best options based on predefined criteria.

For instance, machine learning algorithms can evaluate the properties of different materials and predict how they will perform under various conditions. This not only saves time but also leads to the selection of materials that enhance vehicle durability and performance. Automotive manufacturers like Toyota are leveraging AI to make data-driven decisions in material selection, leading to more sustainable and efficient production practices.

AI in Autonomous Manufacturing

The integration of AI into manufacturing processes is paving the way for more automated and efficient production lines. AI-driven robotics are increasingly being utilized for tasks such as welding, painting, and assembly, enhancing precision and reducing human error. These smart robots can adapt to variations in production, adjusting their actions in real time to optimize workflows.

Furthermore, AI can analyze data from production lines to predict maintenance needs, minimizing downtime and ensuring a smoother manufacturing process. Companies like Volkswagen and Mercedes-Benz are implementing AI-enhanced robotics in their factories, leading to more streamlined and efficient operations.

Predictive Maintenance

One of the significant advantages of AI in manufacturing is its ability to facilitate predictive maintenance. By monitoring equipment performance and analyzing historical data, AI can identify patterns that indicate when a machine is likely to fail.

This proactive approach allows manufacturers to address potential issues before they lead to costly downtime. For example, using AI-powered sensors and analytics, automotive companies can schedule maintenance during non-peak hours, ensuring production continuity. This not only enhances efficiency but also reduces costs associated with unexpected breakdowns.

Enhanced Quality Control

AI is revolutionizing quality control processes in automotive manufacturing by enabling real-time monitoring and analysis. AI algorithms can analyze images captured by cameras installed along the production line, detecting defects or inconsistencies in components at an early stage. This immediate feedback allows manufacturers to address issues before they escalate, ensuring that only high-quality products make it to market. Companies like Honda are employing AI for quality assurance, leading to improved product reliability and customer satisfaction.

Conclusion

The integration of Artificial Intelligence in automotive design, prototyping, and manufacturing represents a seismic shift in how the industry operates. As vehicles become more complex and consumer demands evolve, AI stands at the forefront of innovation, enabling manufacturers to meet these challenges head-on. From generative design that accelerates the creative process to AI-driven automation that streamlines production lines, the benefits are profound.

AI’s role in prototyping allows for faster iterations and reduced costs, while its influence in manufacturing enhances precision, quality, and predictive maintenance capabilities. By leveraging data-driven insights and intelligent algorithms, automotive companies can make informed decisions that optimize material selection, enhance safety, and improve overall performance. Furthermore, AI empowers teams to collaborate more effectively, ensuring that the design and production processes are not only efficient but also aligned with market needs.

As we look to the future, the potential for AI in the automotive sector is immense. Continued advancements in machine learning, robotics, and data analytics will unlock new possibilities for vehicle innovation and production efficiency. Embracing AI will not only enable automotive manufacturers to thrive in a competitive landscape but will also pave the way for a more sustainable and intelligent transportation ecosystem.

In conclusion, AI is not just a tool; it is a catalyst for transformation in the automotive industry. By harnessing its capabilities, manufacturers can drive the future of mobility, creating vehicles that are not only smarter and more efficient but also safer and more aligned with the needs of consumers and society as a whole. As we continue to explore the depths of AI’s potential, the automotive industry stands poised to redefine what is possible in vehicle design, prototyping, and manufacturing.