Smart factories are becoming increasingly dependent on real-time decision-making, automation, and intelligent systems.

Predictive maintenance plays a key role in ensuring uninterrupted operations by identifying early signs of equipment failures before they occur.

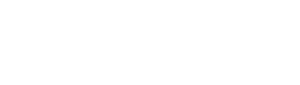

While traditional processors can struggle with the massive data volume and latency requirements, Field-Programmable Gate Arrays offer a powerful solution.

With their parallel processing capabilities and ability to handle high-speed data streams, FPGAs are transforming predictive maintenance in modern industrial environments.

What Is Predictive Maintenance?

Predictive maintenance is a proactive approach that uses sensors, machine data, and analytics to predict equipment failures before they disrupt operations.

Instead of relying on scheduled maintenance or waiting for breakdowns, predictive maintenance systems continuously monitor machinery to detect anomalies such as vibration spikes, temperature variations, pressure changes, or abnormal noise patterns.

This helps manufacturers reduce downtime, extend asset lifecycle, and optimize operational efficiency.

Why FPGAs for Predictive Maintenance?

FPGAs offer a unique combination of flexibility, performance, and low latency, making them ideal for predictive maintenance applications.

Unlike CPUs and GPUs, FPGAs can be reconfigured to execute specific workloads, enabling real-time data processing at the edge.

They can handle continuous sensor input, run AI/ML models, accelerate pre-processing, and deliver instant insights without relying on cloud connectivity.

Key advantages of using FPGAs:

- Real-time edge analytics with microsecond-level latency

- High parallelism for handling large sensor data streams

- Energy-efficient computation for industrial deployments

- Reconfigurability to adapt to changing algorithms or models

- Reliable performance under harsh factory conditions

How FPGA-Powered Predictive Maintenance Works

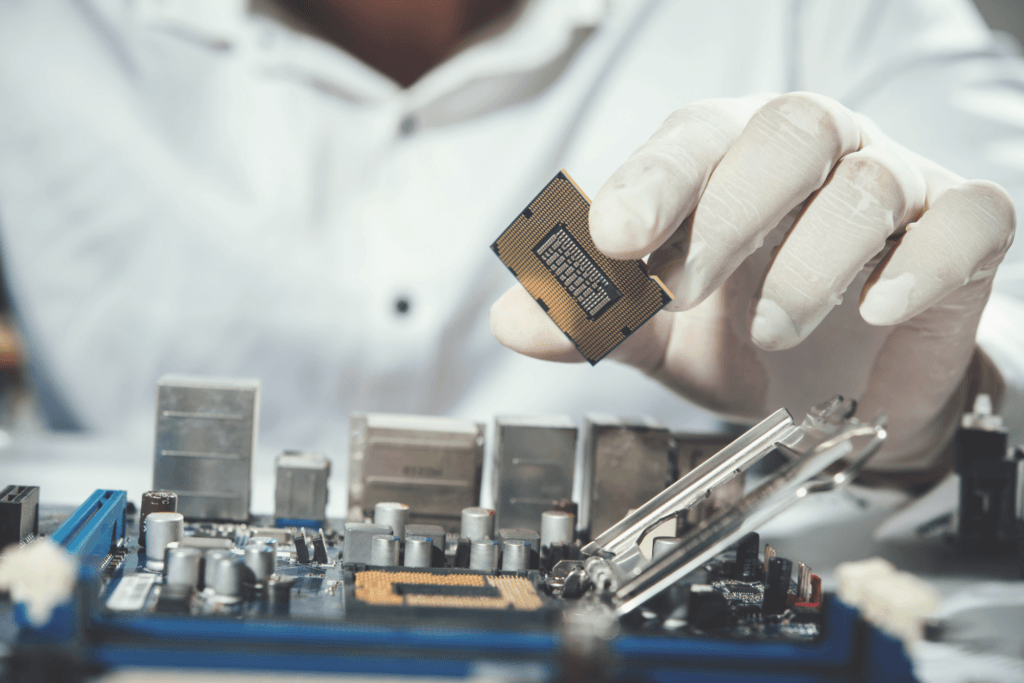

FPGA-based systems integrate seamlessly with factory assets and sensor networks. They capture raw data from various sensors, vibration, acoustic, thermal, and electrical, and process it locally.

Key steps in the workflow:

Data Acquisition: High-speed ADCs and sensor modules collect real-time data from machines.

Signal Pre-processing: FPGAs perform filtering, noise reduction, FFT analysis, and feature extraction.

AI/ML Inference: Lightweight or custom ML models run directly on the FPGA fabric, detecting early signs of faults.

Decision Making & Alerts: Based on detected anomalies, the system generates alerts or triggers automated actions.

Cloud/SCADA Integration: Processed insights can be sent to factory management systems for long-term analysis.

Applications of FPGA-Based Predictive Maintenance

FPGAs are applicable in various industrial scenarios where response time and reliability are critical.

Common applications include:

- Motor and Drive Monitoring: Real-time vibration and current analysis for motors, compressors, and pumps.

- HVAC System Optimization: Detecting irregularities in temperature and airflow patterns.

- Robotics Monitoring: Ensuring robotic arms maintain precision and avoid unexpected failures.

- Conveyor and Assembly Line Systems: Monitoring belt speed, load balance, and mechanical wear.

- Energy Systems: Continuous monitoring of electrical parameters and power electronics.

Benefits for Smart Factories

Integrating FPGAs into predictive maintenance systems brings measurable improvements to manufacturing operations.

Major benefits:

- Reduced Downtime: Early fault detection minimizes unexpected production halts.

- Improved Asset Performance: Machines run efficiently with timely maintenance interventions.

- Lower Maintenance Costs: Preventive actions reduce the need for expensive emergency repairs.

- Enhanced Safety: Prevents accidents caused by mechanical or electrical failures.

- Scalable and Future-Proof: FPGA reconfigurability supports new algorithms and trends without hardware changes.

FPGAs and AI: A Powerful Combination for Predictive Maintenance

The increasing adoption of AI in smart factories makes FPGAs even more valuable. AI models such as anomaly detection, pattern recognition, and predictive forecasting can run directly on FPGA fabric. With AI accelerators, manufacturers can implement:

- Real-time neural network inference

- Adaptive learning models for dynamic environments

- Compressed AI models optimized for low latency

This combination enables ultra-fast predictions, ideal for high-value industrial machinery.

Challenges and Considerations

While FPGAs offer strong capabilities, successful deployment requires planning and expertise.

Key considerations:

- Development Complexity: Designing FPGA solutions demands specialized skills in HDL, RTL, and optimization.

- Integration Effort: Requires coordination with existing SCADA, PLCs, and IT systems.

- Cost: Initial investment may be higher than software-based systems.

However, long-term operational gains significantly outweigh these challenges.

Future of FPGA-Based Predictive Maintenance

Emerging technologies such as AI, CXL-based accelerators, and next-generation FPGAs are strengthening predictive maintenance frameworks.

Future smart factories will rely more on distributed edge intelligence, dynamic system monitoring, and real-time decision-making areas where FPGAs excel.

As industrial automation expands, FPGA-powered predictive maintenance will become a foundational technology ensuring efficiency, reliability, and zero-downtime production.

Conclusion

FPGAs are redefining predictive maintenance by enabling ultra-fast, reliable, and intelligent monitoring systems for smart factories.

With real-time analytics, AI acceleration, and adaptability, FPGA-powered solutions empower manufacturers to reduce downtime, extend machine life, and improve factory performance.

As industries move toward smarter and more autonomous operations, FPGAs will play a critical role in building predictive maintenance systems that are efficient, scalable, and future-ready.

![What is FPGA Introduction to FPGA Basics [2023] computer-chip-dark-background-with-word-intel-it](https://fpgainsights.com/wp-content/uploads/2023/06/computer-chip-dark-background-with-word-intel-it-300x171.jpg)