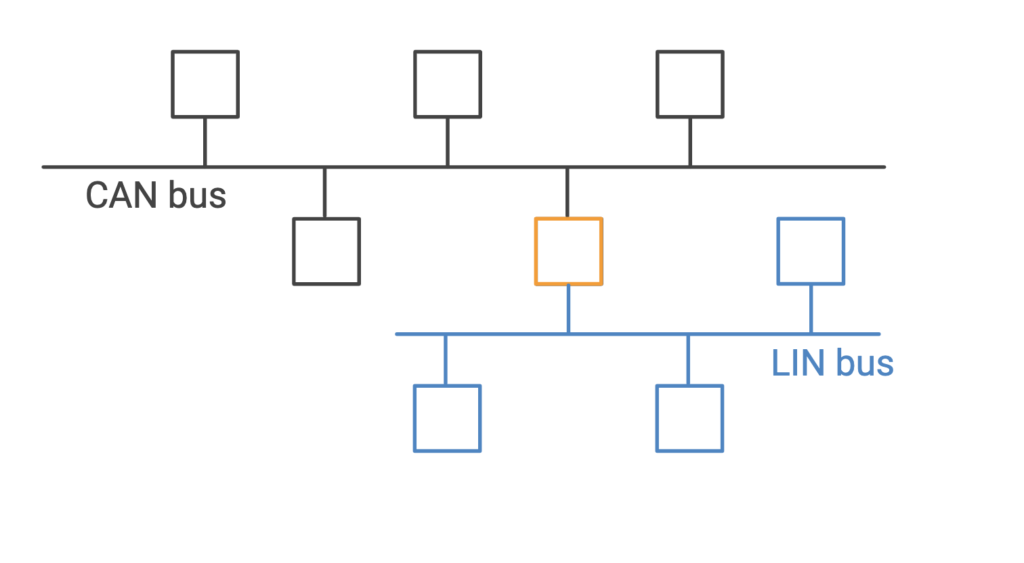

LIN, which stands for Local Interconnect Network, is a widely used communication protocol in the automotive industry. It was developed as a cost-effective alternative to more complex and expensive protocols such as CAN (Controller Area Network) for low-speed applications.

The LIN protocol provides a reliable and efficient way for various electronic control units (ECUs) in a vehicle to communicate with each other.

The Local Interconnect network (LIN) protocol operates on a master-slave communication model, where one device acts as the master and controls the communication with multiple slave devices.

This enables efficient data exchange between different ECUs, allowing them to work together seamlessly.

LIN

The simplicity and affordability of LIN make it an ideal choice for automotive applications that require reliable communication over short distances.

Understanding the LIN protocol

The LIN protocol is based on a serial communication interface, where data is transmitted bit by bit over a single wire.

It uses a master-slave architecture, where the master device initiates the communication and controls the timing of the data transmission.

The slave devices respond to the master’s commands and provide the requested information or perform the required actions.

The LIN protocol supports a maximum data rate of 20 Kbps, which is sufficient for most automotive applications that require low-speed communication.

It uses a master-slave arbitration mechanism to ensure that only one device transmits data at a time, preventing data collisions and ensuring reliable communication.

Additionally, the LIN protocol incorporates error-checking mechanisms to detect and correct transmission errors, further enhancing its reliability.

Benefits of using LIN in automotive applications

There are several key benefits to using LIN in automotive applications. Firstly, the low-cost nature of LIN makes it highly attractive for manufacturers who want to incorporate communication capabilities into their vehicles without significantly increasing the overall cost. This allows for the widespread adoption of LIN as a standard communication protocol in the automotive industry.

Secondly, the simplicity of the LIN protocol makes it easy to implement and integrate into existing automotive systems. The straightforward nature of LIN communication reduces the complexity of the wiring harness and simplifies the overall design of the vehicle’s electronic systems. This results in reduced development time and cost for automotive manufacturers.

Furthermore, LIN offers excellent fault tolerance and robustness, making it suitable for automotive applications that require reliable communication in harsh environments. The LIN protocol’s error-checking mechanisms ensure the integrity of data transmission, even in the presence of electrical noise or other interference commonly found in automotive environments.

LIN master-slave communication concept

The master-slave communication concept is at the core of the LIN protocol. In this communication model, one device, the master, takes control of the communication and coordinates the data exchange with multiple slave devices. The master device initiates the communication by sending a request to a specific slave device, and the slave device responds with the requested information or performs the required action.

The master device controls the timing of the communication, ensuring that each slave device receives the necessary data at the right time. This allows for efficient and synchronized operation of multiple devices in a LIN network. The master-slave communication concept enables different ECUs in a vehicle to work together effectively, enhancing the overall functionality and performance of the vehicle’s electronic systems.

It is important to note that the master-slave communication concept in LIN does not imply a hierarchical relationship between devices. The master device is responsible for coordinating the communication, but it does not have control or authority over the slave devices. Each device in a LIN network can have specific tasks and responsibilities, and the master device simply facilitates the communication between them.

LIN IP Core: What it is and how it works

A LIN IP Core is a pre-designed intellectual property block that enables the implementation of the LIN protocol in electronic systems. It provides all the necessary hardware and software components required to support LIN communication, making it easy to integrate LIN capabilities into automotive applications.

The LIN IP Core typically consists of a LIN controller, which handles the low-level communication tasks such as bit timing, data transmission, and error checking. It also includes a LIN transceiver, which interfaces with the physical layer of the LIN network and converts the digital signals to analog signals for transmission over the LIN bus.

The LIN IP Core works by receiving commands from the master device and transmitting the requested data or performing the required actions as a slave device. It handles the timing and synchronization of the LIN communication, ensuring that data is transmitted and received accurately. The LIN IP Core also incorporates error-checking mechanisms to detect and correct transmission errors, ensuring reliable communication in automotive applications.

Features and capabilities of a LIN IP Core

A high-quality LIN IP Core offers various features and capabilities that enhance the performance and flexibility of automotive systems. Some of the key features to look for in a LIN IP Core include:

- Support for LIN 2.x and LIN 1.x: A versatile LIN IP Core should support both the LIN 2. x and LIN 1. x versions of the protocol, ensuring compatibility with a wide range of automotive systems.

- Flexible data rates: Configuring different data rates is essential to accommodate the specific communication requirements of different automotive applications.

- Integrated diagnostics: Built-in diagnostic capabilities enable real-time monitoring of the LIN communication, allowing for quick detection and resolution of any issues or faults.

- Low power consumption: An energy-efficient LIN IP Core helps to minimize power consumption in automotive systems, contributing to overall fuel efficiency and sustainability.

- Small footprint: A compact and efficient LIN IP Core reduces the size and complexity of the electronic systems, making it easier to integrate into vehicles with limited space.

Choosing the right LIN IP Core for your project

When selecting a LIN IP Core for your project, it is important to consider several factors to ensure that it meets your specific requirements. Here are some key considerations to keep in mind:

- Compatibility: Ensure that the LIN IP Core is compatible with the version of the LIN protocol required by your application. Additionally, check for compatibility with other hardware and software components in your system.

- Performance: Evaluate the performance specifications of the LIN IP Core, including data rate, latency, and error-checking capabilities. Choose a LIN IP Core that can meet the communication requirements of your application.

- Vendor support: Consider the level of support provided by the IP Core vendor. Look for a vendor with a strong reputation for customer support and a track record of delivering high-quality products.

- Integration ease: Assess the ease of integration of the LIN IP Core into your existing system. Look for documentation, reference designs, and software drivers that can simplify the integration process.

- Cost: Finally, consider the cost of the LIN IP Core and evaluate it in relation to the features and capabilities it offers. Seek a balance between cost-effectiveness and the specific needs of your project.

LIN IP Core implementation and integration considerations

Implementing and integrating a LIN IP Core into an automotive system requires careful planning and consideration. Here are some important factors to keep in mind during the implementation and integration process:

- System architecture: Analyze the overall system architecture and identify the specific roles and responsibilities of each ECU. Determine how the LIN IP Core will fit into the system and how it will interact with other components.

- Hardware design: Design the hardware components of the system, including the LIN bus and the LIN transceiver. Ensure that the hardware design meets the electrical and mechanical requirements of the LIN protocol.

- Software development: Develop the software components required to support the LIN communication. This includes writing the LIN driver, implementing the necessary LIN protocol stack, and integrating the LIN IP Core with the rest of the software system.

- Testing and validation: Thoroughly test and validate the LIN implementation to ensure its reliability and performance. Use simulation tools, hardware-in-the-loop testing, and real-world testing to verify the functionality of the LIN IP Core.

- Documentation and training: Document the implementation process and provide training to the relevant stakeholders. This will ensure that the LIN IP Core can be effectively maintained and supported throughout the lifecycle of the automotive system.

LIN IP Core testing and validation

Testing and validation are critical steps in ensuring the reliability and performance of a LIN IP Core implementation. Here are some key aspects to consider during the testing and validation process:

- Functional testing: Test the functionality of the LIN IP Core by simulating different communication scenarios and verifying the correct operation of the LIN protocol. This includes testing the master-slave communication, data transmission, and error detection and handling.

- Performance testing: Evaluate the performance of the LIN IP Core by measuring its data rate, latency, and response time. Verify that the LIN IP Core can meet the communication requirements of the automotive application under different operating conditions.

- Compatibility testing: Test the compatibility of the LIN IP Core with other hardware and software components in the automotive system. Verify that the LIN IP Core can seamlessly integrate with the rest of the system and communicate effectively with other ECUs.

- Stress testing: Subject the LIN IP Core to stress testing to assess its robustness and fault tolerance. This includes testing the LIN communication under extreme conditions, such as high temperatures, high voltages, and electrical noise.

- Validation testing: Validate the LIN IP Core implementation by conducting real-world testing in an automotive environment. This involves testing the LIN communication in a vehicle or a test bench to ensure its reliability and performance in real-world conditions.

Conclusion

In conclusion, LIN is a powerful communication protocol that offers numerous benefits for automotive applications. The master-slave communication concept of LIN enables efficient data exchange between different ECUs in a vehicle, enhancing the overall functionality and performance of the electronic systems. A LIN IP Core provides a comprehensive solution for implementing the LIN protocol, offering features and capabilities that enhance the performance and flexibility of automotive systems. By carefully considering the specific requirements and following best practices during the implementation and integration process, the full potential of LIN can be unlocked in automotive applications.

Remember to choose a high-quality LIN IP Core that meets your project’s requirements and to thoroughly test and validate the LIN implementation to ensure its reliability and performance. With the right LIN IP Core and a well-executed implementation, you can unlock the power of LIN and enhance the communication capabilities of your automotive systems.